Asbestos Removal Fundamentals Explained

Table of ContentsThe Basic Principles Of Asbestos Removal All About Asbestos RemovalExcitement About Asbestos Removal

The tidy space could be provided with benches, lockers for clothes and valuables, and appropriate storage for respirators. The shower space need to be located between the tidy room and the equipment space. This will make sure that employees leaving the contaminated devices space must travel through the shower room in order to enter the clean room.Hot and cold water products need to be offered close-by in many structures. For hot water lines, it is recommended that high quality rubber pipe be used to avoid breaking and leakage. The shower needs to be supplied with both cold and hot water or with warm water of a continuous temperature in between 40 and 50 Celsius.

It is suggested that there be adequate showers to prevent delays. Needing to wait on access to a shower might trigger some people to hurry through the decontamination procedure or to skip it entirely. The bathroom need to likewise be geared up with clean towels. Infected work clothes, footwear, difficult hats, safety glasses and other equipment must be kept in a location surrounding to the bathroom.

The spaces ought to be arranged so that any person travelling through the workspace need to go through each room and must: decontaminate his/her protective clothing utilizing the vacuum or damp wiping; remove his/her protective clothes; location the protective clothes in the prescribed container; shower; and, eliminate and clean the respirator (asbestos removal).

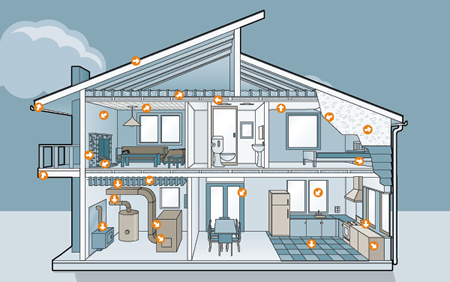

The waste load-out location includes a room constructed into the enclosure, however separated by airlocks from the work location and the location outside the enclosure as shown below. Curtained entrances made from overlapping sheets of polyethylene or other invulnerable materials are utilized to form the air locks. Waste containers are cleaned up by wet cleaning or use of a HEPA vacuum in the work area and then positioned in the waste load-out area.

All about Asbestos Removal

This may consist of using drop sheets made of polyethylene or other material that is invulnerable to asbestos on work surface areas. Care needs to be taken to guarantee that the material utilized does not develop a slipping threat that might put employees at danger of falling. Elimination of Asbestos Outdoors Source: Building And Construction Security Association of Ontario A decontamination facility should be located as close as practicable to the workspace.

The decontamination facility should be built so that any one going into or leaving the work location should pass through each space. Personalized trailers outfitted with 3 room decontamination facilities are readily available for use as decontamination centers. These systems can be moved from one work site to the next and are frequently utilized for outside work.

For work on non-friable ACM that is made with power tools that are not connected to dust-collecting gadgets geared up with click this link HEPA filters, an enclosure of polyethylene or other ideal material should be built, unless walls already enclose the workspace. asbestos removal. The entryways and exits to the enclosure must be fitted with curtains made of polyethylene or other suitable material that is invulnerable to asbestos, on each side (see listed below) and, if the enclosure is opaque, it should be fitted with several transparent windows to allow observation of the entire work area from outside the enclosure.

The building and construction of an enclosure is discussed in the previous area handling preparation for indoor Type 3 operations involving ACM that are explained in paragraphs 1, 2, 3, 4 and 6 of subsection 12( 4 ). Work With Power Tool Not Equipped With Dust Collection Gadget and HEPA Filter Source: Construction Security Association of Ontario There are 3 aspects to the control of asbestos dust: control at the source; separation between the worker and the source; and hygiene measures and treatments.

Keeping ACM wet tends to reduce the number of asbestos fibers that enter into the air and also increases the settling rate of the fibers that are released. The Policy needs that a moistening representative be contributed to water that is utilized to control the spread of dust and fibres.

Enclosures made from polyethylene or other material that is resistant view it to asbestos needs to be utilized on some Type 2 and Type 3 operations to stop the spread of dust from the workspace if the workspace is not enclosed by walls. In many indoor Type 3 operations, the generation of airborne asbestos fibres must likewise be controlled by setting up a ventilation system geared up with HEPA filters and by establishing and preserving an unfavorable atmospheric pressure of 0.

The 25-Second Trick For Asbestos Removal

The upkeep of negative air pressure within the enclosure relative to the area outside the enclosure assists to prevent the spread of fibres and is a requirement for indoor Type 3 operations. Because the unfavorable air system tires air from the enclosure through a HEPA filter, it This Site likewise helps to decrease airborne asbestos concentrations within the enclosure.

Source: Construction Security Association of Ontario When a Type 1 operation includes the elimination of less than one square metre of drywall in which ACM joint-filling compound has actually been used, the product must be moistened and kept wet during the work, unless wetting would create a danger or trigger damage.